News

PVC Coating For Metal Process At VIJAYA

Hello everyone, VIJAYA SAI DIP MOULDING VIETNAM CO., LTD would like to introduce to you the standard plastic embedding, metal-plastic coating process that our company is currently implementing. Please follow the article below.

Contents

What is pvc coating or metal plastic wrap?

PVC coating is widely used in life

>> See also: Metallic plastic wrap: [Complete] the most complete knowledge

PVC Coating Process

Product surface preparation

Before performing the pvc coating process, the surface of the product should be prepared so that it is smooth and dry so that the resin can adhere well and the product achieves the best quality. The product surface preparation steps in the plastic dipping process usually include:

- Product Cleaning: The product should be cleaned with a soap solution or cleaning solution before starting the surface preparation process.

- Product grinding or polishing: After washing, the product should be ground or polished to remove scratches or fingerprints on the surface.

- Remove oil or other dirt: The product needs to be removed from the surface of the oil or other dirt by using a cleaning solution or a disinfectant solution.

- Product drying: After washing and degreasing, the product should be completely dried before performing the resin dipping process.

Grinding the product before dipping helps the resin mixture to adhere better.

Prepare the resin and adhesive mixture

The preparation of the resin and binder mixture in the resin dipping process is one of the important steps to ensure the quality of the product after it is dipped.

-

Choose the right resin and adhesive:Before starting the mixture preparation process, it is necessary to select the resin and binder suitable for the product requirements and the operating conditions. Factors to consider include: strength, toughness, chemical resistance, working temperature, abrasion resistance, hardness, fire resistance and UV resistance.

-

Quantitative mix:After selecting the right resin and adhesive, it is necessary to quantify them to form a mixture of resin and adhesive. The quantitative formula needs to be carefully calculated to ensure the accuracy and uniformity of the mixture.

-

Mixing:After the quantification is completed, it is necessary to mix the resin and binder mixture well. Mixers can be used or mixed by hand to ensure uniformity of the mixture.

Preparation of the resin and adhesive mixture is a decisive step to the quality of the finished product

-

Add grinding aid (if needed):If necessary, a grinding aid can be added to help distribute the resin and binder mixture evenly and avoid uneven adhesion after dipping.

-

Filter the mixture:After mixing the mixture well, it is necessary to filter them to remove impurities that may affect the quality of the product after dipping.

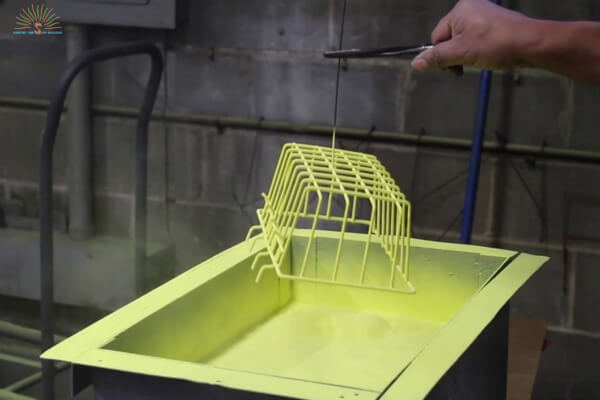

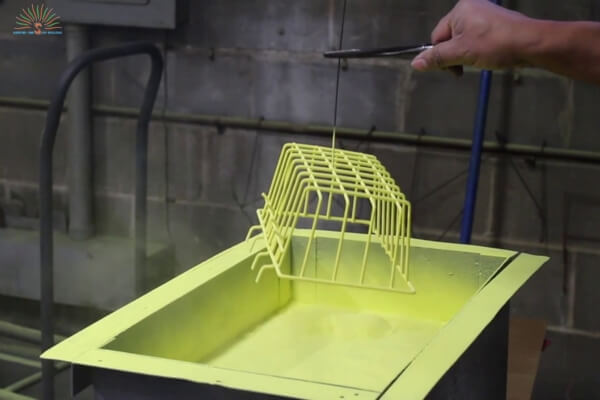

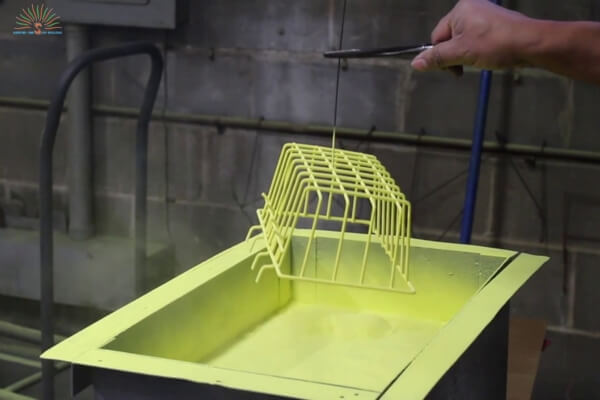

The process of dipping the product into a mixture of resin and adhesive

- Putting the product into the resin and adhesive mixture: This process can be done by various methods such as dipping, spraying or brushing the mixture of resin and adhesive onto the surface of the product.

- Soaking time: After the product is put into the resin and adhesive mixture, it is necessary to let the product soak in this mixture for a certain period of time so that the resin and adhesive mixture can penetrate deeply into the surface. product side.

- Remove the product from the resin and adhesive mixture: After the product has soaked for a sufficient time, it is necessary to remove the product from the resin and adhesive mixture.

PVC Coating process is carried out manually or with the help of machines depending on the product.

The process of drying and heating the product

After the product is dipped in the resin and binder mixture, the next process is to dry and heat the product to achieve the required mechanical, chemical and strength properties. This stage includes the following steps:

- Drying: The product is removed from the resin and adhesive mixture and hung or placed on a rack to dry naturally for about 1 to 2 hours. If the product has a complicated shape or has a lot of gaps, a fan or dryer can be used to dry it faster.

- Product heating: After the product has been completely dried, it is put into a kiln to achieve the desired chemical and mechanical properties. The firing process can be done at a variety of temperatures depending on the resin and adhesive used. Usually, the product is baked for about 2 to 4 hours at a temperature of 80 to 120 degrees Celsius.

- Grinding and finishing the product: After the product has been completely calcined, it is ground to achieve the required gloss and smoothness. After that, the product is checked for quality and perfected before being put into use.

After dipping, the product can be left to dry naturally

To sum it up, the drying and firing of the product is an impossible step in the resin dipping process. The correct and complete implementation of these steps will help the product achieve the desired mechanical, chemical and durability properties, thereby meeting the requirements of the customer.

Check product quality after completion:

The stage of product quality inspection after completion in pvc coating includes the following steps:

- Adhesion test: The product after dipping the plastic needs to have good and uniform adhesion on the entire surface. To test the adhesion, we can use a razor or tape to check if the plastic layer has peeled off.

- Check coating thickness: The thickness of the plastic coating needs to meet product specifications. To check the thickness, we can use a thickness gauge.

- Roughness test: The product after being dipped in plastic needs to have a nice roughness to ensure aesthetics and corrosion resistance. To check the roughness, we can use the glass surface or the roughness meter.

- Test for mechanical strength: The product after being dipped in plastic needs to meet the requirements for mechanical strength such as flexural strength, tensile strength, impact strength. To test the mechanical strength, we can use a mechanical strength tester or conduct a test on the product.

- Test for corrosion resistance: The product after being dipped in plastic needs to have good corrosion resistance to ensure the durability and life of the product. To test the corrosion resistance, we can use specialized testing equipment or conduct tests on the product.

All product quality checks after completion in the pvc coating for metal process are very important to ensure the product meets the customer’s specifications and quality.

Prestigious, high-quality pvc coating for metal address

- Material: Soft PVC

- Operating temperature: Up to 105oC

- Operating voltage: Up to 600V

- Color: White, Black, Red, Yellow, Green, Blue, Gray, Brown.. can be customized according to customer requirements.

- Products: All products and equipment according to customer requirements.

VIJAYA dips all products and equipment in plastic according to customer requirements. See product details here

Contact Info:

For more information, advice and request a quote about the service, please contact the information below:

VIJAYA SAI – VINA DIP MOULDING COMPANY LIMITED

Tax code: 0107006928

Office address: Petrolimex Bldg No.9/84 Ngockhanh Str., Hanoi, Vietnam

Factory address: Lot 1-16 Duong Lieu IZ, HoaiducDist., Hanoi, Vietnam

Tel/ Fax: 0243 776 3021 – Email: cuongnm@vijaya-vina.com.vn

Hot line: 0974 876 389 – 0869 396 388

Website: https://vijaya-vina.com.vn

Tiếng Việt

Tiếng Việt