News

Metal Plastic Wrap: [Complete] The Most Complete Knowledge

The demand for metal plastic wrap is increasing day by day, but the knowledge about this field has not been fully provided to users. Therefore, VIJAYA SAI DIP MOULDING VIETNAM CO., LTD is a leading unit in metal plastic wrap, please provide the most complete knowledge about this service.

Contents

- 1 What is metal plastic wrap?

- 2 Benefits of metal plastic wrap products

- 3 Types of plastic used to wrap metal

- 4 Production process of metal plastic coated products

- 5 Applications of metal plastic coated products

- 6 Notes when using metal-plastic coated products

- 7 Prestigious, high quality metal plastic wrap address

What is metal plastic wrap?

Metal plastic wrap is the process of protecting metal surfaces by coating a layer of plastic on the metal surface to prevent external influences from causing corrosion or damage. This process is an important part of industry and construction, and is widely used in many different applications.

Other names: embedding metal plastic, coating plastic on metal, embedding plastic

Benefits of metal plastic wrap products

- Protects metal surfaces from the effects of the external environment, including corrosion and oxidation.

- Improves the durability and service life of metal surfaces.

- Produces a smooth and easily cleaned surface for use in medical, food or safety applications.

- Improve the aesthetics of metal surfaces.

- Use in constructions such as bridges, tunnels, roads and railways to protect metals from the effects of weather and other external factors.

Types of plastic used to wrap metal

Epoxy Resin

The boat has a shiny surface after being coated with epoxy resin

Vinly Ester Plastic

Vinyl ester coating chemical containers

Polyester resin

Cover the tank by polyester plastic

PVC plastic

PVC is widely used to protect metal surfaces

PE (Polyethylene) Plastic

PE coated water pipes become more resilient

PP (Polypropylene) Plastic

PP plastic tank

PA (Polyamide) Resin

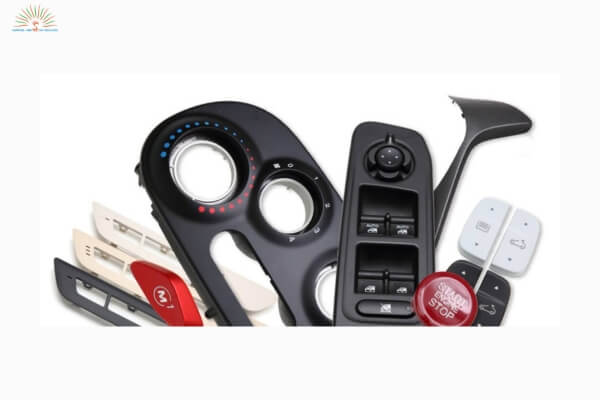

PA plastic is used to produce automotive components

PET (Polyethylene Terephthalate) Plastic

PET Plastic Straps

PU (Polyurethane) Plastic

Wheel cover with PU

Each resin has different properties and properties, depending on the application and requirements of the metal-plastic embedded product.

Production process of metal plastic coated products

Metal surface preparation and treatment

Metal surfaces need to be cleaned and polished to remove surface stains, grease and impurities.

Primer

Plastic coating

Wait for it to dry

Check product quality

- Mechanical strength test: This is one of the most important factors of metal-plastic embedded machining products. Check the mechanical strength by performing tests such as bending, tensile, compression… to ensure that the product has high strength and meets the necessary technical requirements.

- Check the thickness of the plastic coating: The plastic coating should be thick enough to protect the metal from external influences. Check the thickness of the plastic coating with specialized thickness gauges.

- Check gloss and color: The gloss and color of metal-plastic coated products are important factors in evaluating the product’s aesthetic appeal. Check the gloss and color of the product using gloss meters and standard color palettes.

- Chemical resistance test: Metal-plastic coated products need to be able to withstand chemicals and solvents during use. Test for chemical resistance by placing the product in a chemical environment and monitoring the product for changes.

- Thermal endurance test: Metal-plastic coated products need to be resistant to high temperatures and not deform during use. Test the heat resistance by placing the product in a high-temperature environment and monitoring the change of the product.

All methods of quality control of metal-plastic coated products should be performed by professionals and using specialized measuring equipment to ensure accurate and reliable results.

Applications of metal plastic coated products

Metallic plastic sleeve

Metallic plastic sleeve

Protect metal surface

Metal objects and equipment

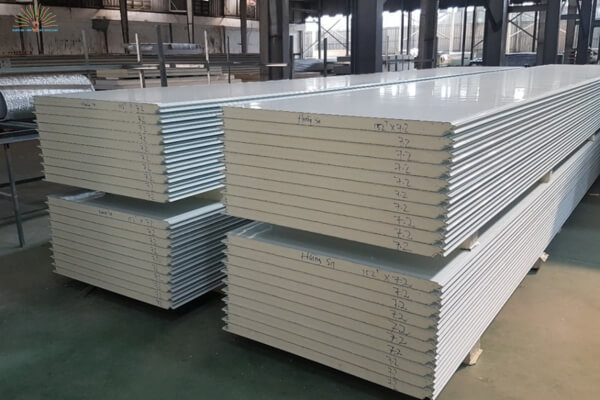

Metallic plastic wrap

Metallic plastic wrap is used in construction works, retaining walls, waterproof panels, decorative coatings, electric poles…

Metal coated panel

Electronic

Electronic components

Producing household appliances

Clothes dryer covered with plastic

Oil pipeline construction

Oil delivery system

Notes when using metal-plastic coated products

Product preservation

Use the product properly

Periodic product inspection

Clean the product periodically

Protect products from external agents

Prestigious, high quality metal plastic wrap address

- Material: Soft PVC

- Operating temperature: Up to 105oC

- Operating voltage: Up to 600V

- Color: White, Black, Red, Yellow, Green, Blue, Gray, Brown.. can be customized according to customer requirements.

- Products: All products and equipment according to customer requirements.

Our company’s PVC embedded products

PVC (Polyvinyl chloride) plastic has many advantages, including:

- Good fire resistance: PVC plastic has a high fire resistance, so it is widely used in applications requiring high safety such as the production of insulating materials and construction products.

- Good mechanical properties and electrical insulation: PVC plastic has high rigidity and strength, so it is used to manufacture mechanical products, machinery and construction materials. In addition, PVC also has good electrical insulators, helping to protect electronic components from external influences.

- UV resistance: PVC plastic has good UV resistance, helping to protect the product from the effects of the sun.

- High strength: PVC has the ability to withstand the effects of temperature, acids, alkalis and other chemicals, making it suitable for use in harsh environments.

- High recyclability: PVC is highly recyclable, helping to reduce the impact of plastic waste on the environment.

For more information, consultation and request for a quote on the service, please contact us using the information below:

VIJAYA SAI – VINA DIP MOULDING COMPANY LIMITED

Tax code: 0107006928

Office address: Petrolimex Bldg No.9/84 Ngockhanh Str., Hanoi, Vietnam

Factory address: Lot 1-16 Duong Lieu IZ, HoaiducDist., Hanoi, Vietnam

Tel/ Fax: 0243 776 3021 – Email: 0869 396 388

Hot line: 0974 876 389 – 0869 396 388

Website: https://vijaya-vina.com.vn

Tiếng Việt

Tiếng Việt