Machine Component Covers – Various Types of PVC Plastic Caps

- Product Name: Machine Cover Cap, Plastic Cover, End Cap

- Material: Soft PVC

- Operating Voltage: Up to 36 kV

- Application: Protection, insulation for indoor and outdoor use

- Color: Blue – Red – Yellow – Gray – White (customizable upon request)

Contents

- 1 Description of Machine Component Covers

- 2 Functions and Applications of Machine Component Covers:

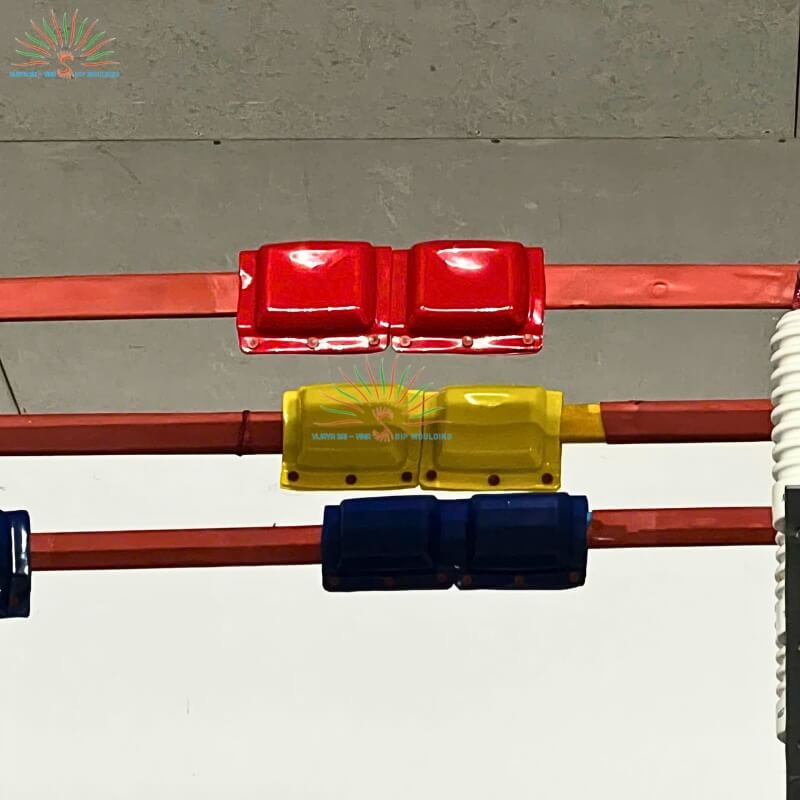

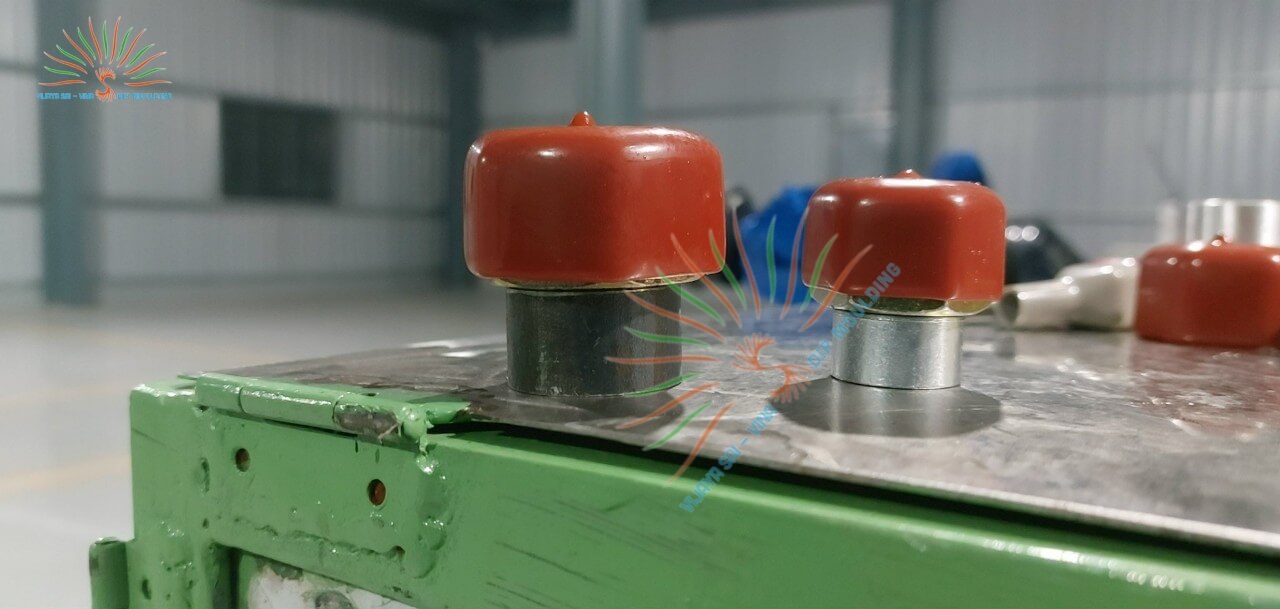

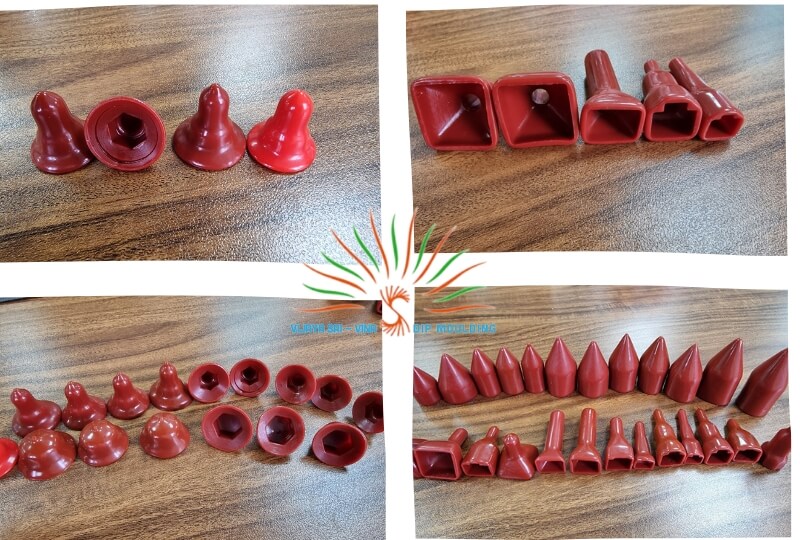

- 3 Product Images of Machine Component Covers:

- 4 Technical Specifications of Machine Component Covers:

- 5 Advantages of PVC Plastic Machine Component Covers:

- 6 Other Types of Plastic Covers by VIJAYA:

- 6.1 Busbar Joint Cover: Covers for electrical busbar connections.

- 6.2 Battery Terminal Caps: Protective covers for battery terminals.

- 6.3 Bolt and Nut Caps: Protective caps for bolts and nuts.

- 6.4 Cable End Covers: Insulating caps for electrical cable ends and terminals.

- 6.5 Connector Terminal Covers: Protective caps for electrical connectors.

- 6.6 Electrical Lug Covers: Protective caps for electrical terminal lugs.

- 6.7 Quality Certifications:

- 6.8 Manufacturing Facility:

- 7 Machine Component Cover Pricing

Description of Machine Component Covers

Machine component covers (also known as protective caps, lids, or shields) are mechanical elements used to enclose, protect, and shield internal components and parts of machinery or equipment. These covers are typically made from materials such as metal, plastic, composite, or other materials suitable for specific applications.

VIJAYA provides various types of machine component covers made from soft PVC plastic.

Functions and Applications of Machine Component Covers:

- Protection: Covers protect critical machine components from external influences such as dust, water, liquids, mechanical impacts, and collision risks. They help keep internal parts safe and shield them from unwanted environmental effects.

- Shielding and Stability: These covers act as shields and help keep parts in their precise and stable positions. They prevent displacement, misalignment, or axial shifts during operation.

- Insulation and Anti-Static Properties: In some cases, covers provide insulation or anti-static functions, protecting components from static electricity or preventing hazardous static discharge scenarios.

- Accessibility and Maintenance: Covers can be designed for easy removal, allowing quick access to internal parts for maintenance, inspection, and repair. This feature saves time and effort for routine maintenance tasks.

- Aesthetic and Branding: Covers can be designed decoratively to enhance the appearance of machinery or products, thus increasing brand recognition.

Product Images of Machine Component Covers:

Technical Specifications of Machine Component Covers:

- Hardness (Shore A): 50 – 65

- Breakdown Voltage: ≥ 50kV

- Operating Voltage: Up to 36 kV

- Short-Term Heat Resistance (10s): ≥ 260°C

- Continuous Heat Resistance (10min): ≥ 180°C

- Flame Resistance Rating: FV0

- Applicable Standards: IEC 60439, IEC 60529

- Material: Soft PVC Plastic

- Tear Strength: >15kN/m

- UV Aging Resistance: >5000h

- Colors: Blue – Red – Yellow – Gray – White (customizable)

- Products: Various types of plastic caps, sealing caps (customizable per customer requirements)

Advantages of PVC Plastic Machine Component Covers:

Machine component covers made from PVC (Polyvinyl Chloride) plastic offer several advantages:

- Corrosion Resistance: PVC has excellent corrosion resistance, remaining unaffected by water, chemicals, or harsh environments. This ensures high durability and superior protection for internal components.

- Durability and Impact Resistance: PVC possesses strong mechanical properties, making the covers highly durable and resistant to impact, thereby protecting internal parts from mechanical damage.

- Good Insulation Properties: PVC provides excellent electrical insulation, preventing electric flow and reducing electrical-related risks. It is ideal for shielding and insulating electrical components and systems.

- Easy to Manufacture and Install: PVC is easy to process, cut, drill, bend, and install, allowing covers to be customized to fit specific applications and easily mounted on machinery and equipment.

- Cost-Effective: PVC is more affordable compared to other materials like metal, making PVC machine component covers an economical choice for protection and shielding.

However, it is important to note that PVC has some limitations, such as limited heat resistance and unsuitability for high-temperature environments. Before selecting PVC covers, application temperature and environmental conditions should be considered to ensure compatibility.

Other Types of Plastic Covers by VIJAYA:

Busbar Joint Cover: Covers for electrical busbar connections.

Battery Terminal Caps: Protective covers for battery terminals.

Bolt and Nut Caps: Protective caps for bolts and nuts.

Cable End Covers: Insulating caps for electrical cable ends and terminals.

Connector Terminal Covers: Protective caps for electrical connectors.

Electrical Lug Covers: Protective caps for electrical terminal lugs.

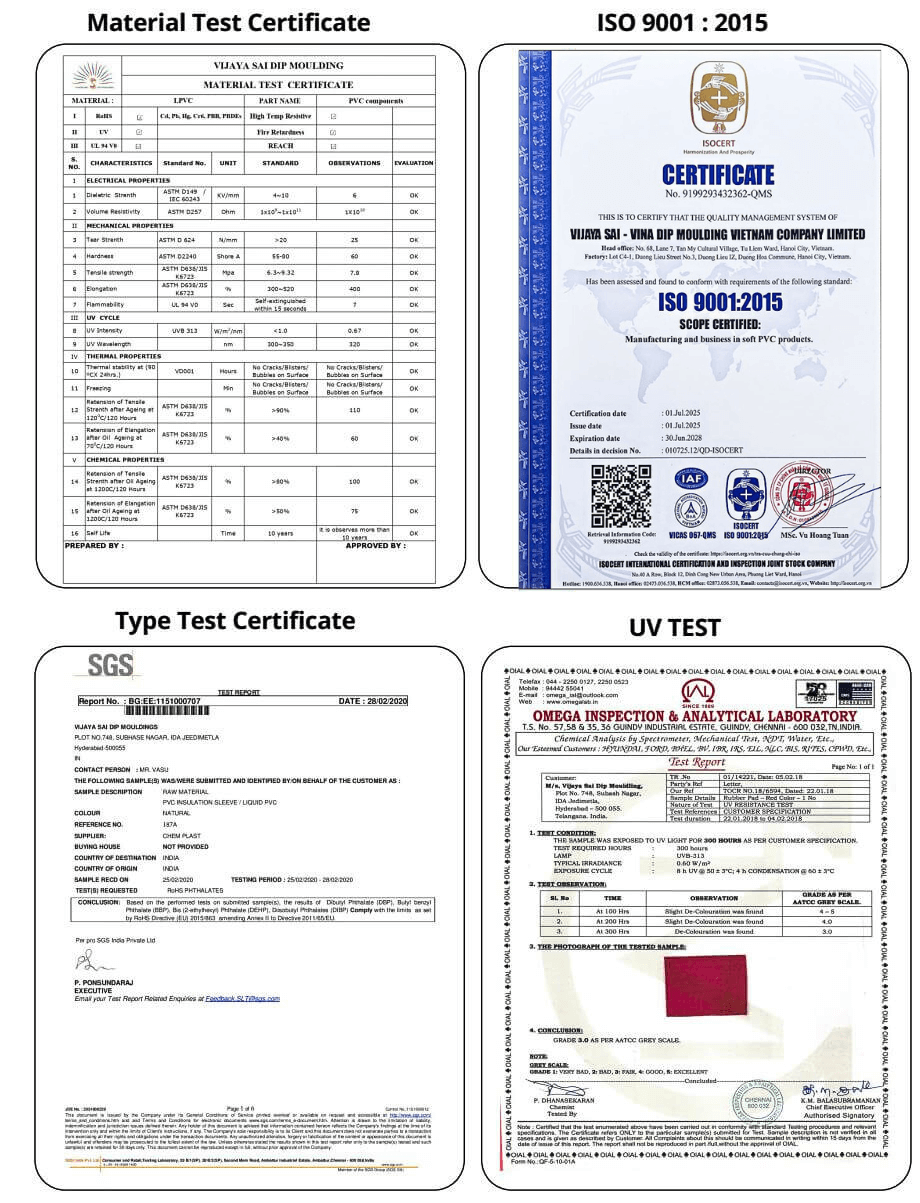

Quality Certifications:

Manufacturing Facility:

Machine Component Cover Pricing

VIJAYA SAI DIP MOULDING VIETNAM Co., Ltd. manufactures a wide range of electrical and thermal insulation plastic covers at competitive prices with fast production times.

For detailed information, consultation, and price quotations for machine component covers, plastic protective caps, and price lists, please contact us:

VIJAYA SAI – VINA DIP MOULDING COMPANY LIMITED

Tax code: 0107006928

Office address: Petrolimex Bldg No.9/84 Ngockhanh Str., Hanoi, Vietnam

Factory address: Lot 1-16 Duong Lieu IZ, HoaiducDist., Hanoi, Vietnam

Tel/ Fax: 0243 776 3021 – Email: cuongnm@vijaya-vina.com.vn

Hotline/ Zalo: 0974 876 389 – 0869 396 388 – 0869 317 388

Website: https://vijaya-vina.com.vn

Youtube Channel: https://www.youtube.com/@vijaya-vina

Fanpage: https://www.facebook.com/profile.php?id=100088634359963

Tiếng Việt

Tiếng Việt