News

What is Soft Insulating Plastic? Characteristics and Common Applications

Soft insulating plastic is an essential material in many industries, providing protection against electrical risks and ensuring the durability of equipment. With numerous outstanding advantages, soft insulating plastic is widely used in various devices and systems. Let’s explore its characteristics and common applications in detail.

Contents

- 1 1. Introduction to Soft Insulating Plastic

- 2 2. Technical Characteristics of Soft Insulating Plastic

- 3 3. Applications of Soft Insulating Plastic

- 4 4. The Most Common Soft Insulating Plastic Products Today

- 5 5. Advantages of Soft Insulating Plastic Compared to Other Materials

- 6 6. Manufacturing Process and Quality Standards

- 7 7. How to Choose High-Quality Soft Insulating Plastic

- 8 8. Usage and Storage Guidelines for Soft Insulating Plastic

- 9 9. Conclusion

1. Introduction to Soft Insulating Plastic

Soft insulating plastic is an insulation material widely used in electrical, electronic, telecommunications, mechanical, and construction systems. With its flexible nature, high durability, and heat resistance, soft insulating plastic helps prevent electrical leakage, protect equipment, and extend the lifespan of systems. This material plays a crucial role in ensuring safety and efficiency for devices and installations.

Soft insulating plastic is used for coating and protecting metal surfaces and products such as plastic-coated U-bolts.

2. Technical Characteristics of Soft Insulating Plastic

- Excellent insulation properties: Soft insulating plastic provides outstanding electrical insulation, preventing electrical leakage and protecting users from electric shocks.

- Flexibility and durability: With high elasticity, soft plastic can be easily bent, making it suitable for applications requiring flexibility.

- Moisture resistance and heat tolerance: Soft insulating plastic can withstand humid environments and high temperatures, increasing the lifespan of equipment.

- Safety and non-toxicity: Soft insulating plastic is safe for users and environmentally friendly, containing no harmful substances.

3. Applications of Soft Insulating Plastic

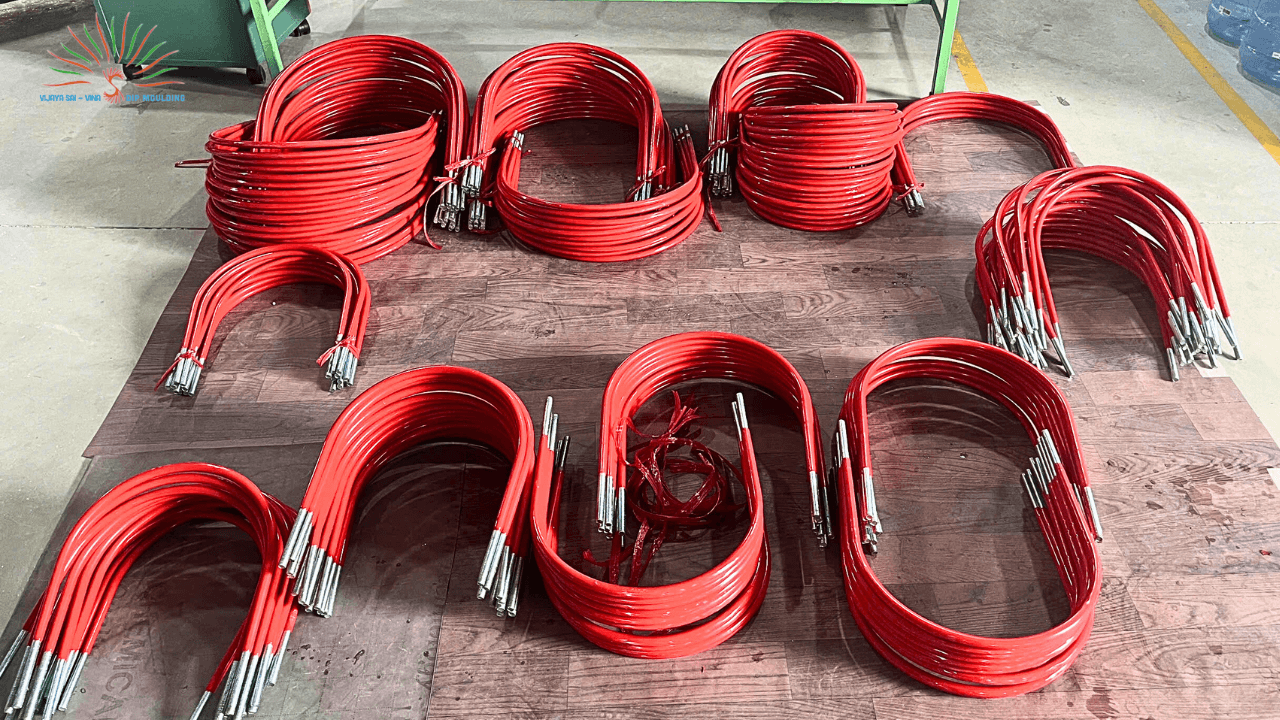

- In the electronics and power industry: Used for making cables, protective tubing for electrical wires, and insulation casings for components.

- In construction and telecommunications: Products such as joint covers and wire coatings help protect telecommunications and electrical systems in construction projects.

- In mechanical engineering: Widely applied for insulating electrical components and sensors in machinery, coating and protecting cables, minimizing electrical leakage risks, and ensuring safe usage.

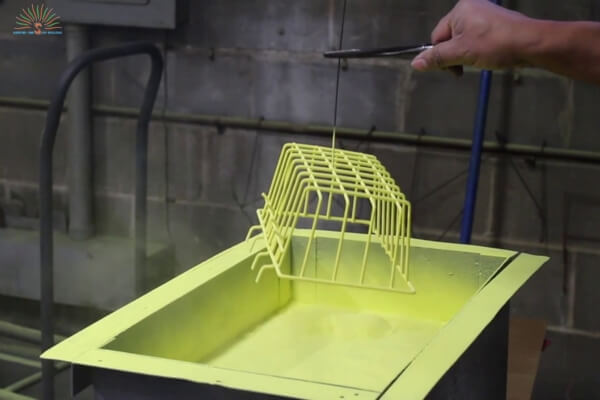

Some applications of soft insulating plastics

4. The Most Common Soft Insulating Plastic Products Today

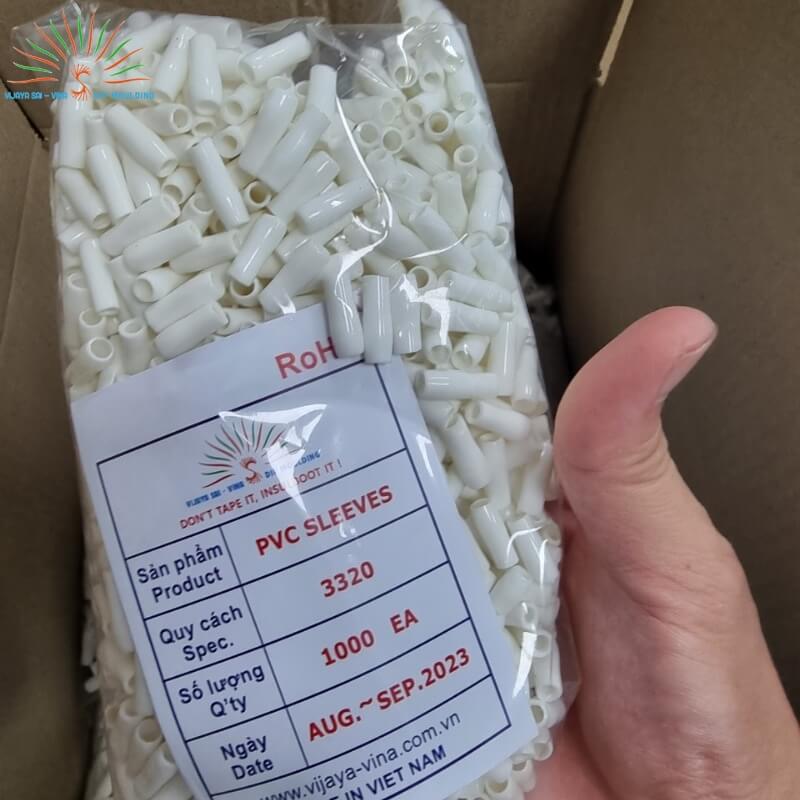

Currently, soft insulating plastic is used in various products to meet diverse industry needs. Below are some of the most common products:

- Busbar Joint Covers: Used in electrical cabinets and control panels, busbar joint covers protect busbars from environmental impacts and prevent electrical leakage.

- Bolt & Nut Caps: These caps protect bolt joints from moisture and corrosion while improving the aesthetics of installations.

- Terminal Lug Covers: Widely used in electrical systems for insulation and oxidation prevention of terminal lugs, ensuring operational safety.

- Battery Terminal Covers: These covers isolate and protect battery terminals, preventing short circuits and ensuring user safety.

- Cable End Caps: Protect cable ends from dust, moisture, and external elements while maintaining insulation effectiveness.

- Contact Covers: Used for insulating and protecting contact points in electrical systems, preventing leakage and ensuring user safety.

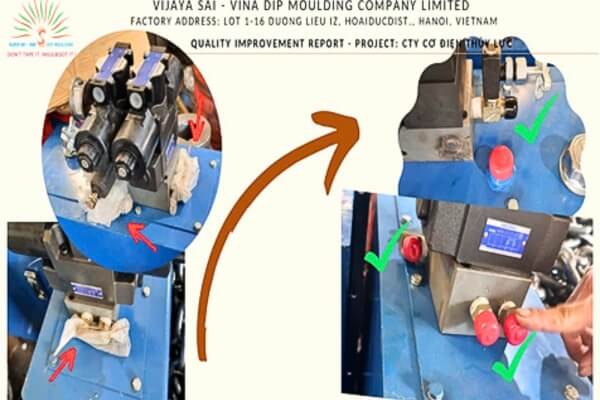

- Plastic-Coated Metal: Designed to coat metal objects, providing insulation, rust resistance, and increased durability.

5. Advantages of Soft Insulating Plastic Compared to Other Materials

Compared to other insulation materials such as rubber and PVC, soft insulating plastic offers many superior advantages:

- Greater flexibility and durability: Soft plastic allows for easier installation and has higher durability than many other materials.

- Better heat and moisture resistance: Soft insulating plastic outperforms PVC in heat and moisture resistance, providing long-term equipment protection.

- Cost-effectiveness: With its long lifespan and excellent protective capabilities, soft insulating plastic reduces maintenance and repair costs.

6. Manufacturing Process and Quality Standards

Soft insulating plastic is manufactured under strict processes, from material selection to fabrication, ensuring high quality. Products made from soft insulating plastic often meet international standards such as IEC, CE, and RoHS, guaranteeing safety and durability.

7. How to Choose High-Quality Soft Insulating Plastic

- Identifying high-quality products: Premium soft insulating plastic products typically feature excellent elasticity, durability, and resistance to harsh environments. They do not crack or break easily.

- Choosing a reputable supplier: To ensure quality, purchase from suppliers with standard certifications and reliable warranty policies.

8. Usage and Storage Guidelines for Soft Insulating Plastic

- Usage notes: Proper use ensures insulation effectiveness and product longevity. Avoid exposure to strong chemicals and high temperatures.

- Storage: Keep products in dry, cool places, away from direct sunlight, to maintain their insulating properties.

9. Conclusion

Soft insulating plastic is an ideal material for protecting electrical systems and electronic devices, thanks to its excellent insulation properties, durability, and flexibility. To ensure effectiveness and longevity, choose soft insulating plastic products from reputable suppliers and follow storage and usage guidelines.

Vijaya Sai Dip Moulding Vietnam Co., Ltd. specializes in manufacturing top-quality soft insulating plastic products that meet international standards. We are committed to providing optimal insulation solutions, ensuring safety and durability for various systems. With advanced technology and extensive experience, we are always ready to supply high-quality products that meet the most demanding market requirements.

Một số hình ảnh sản phẩm:

Contact Information:

VIJAYA SAI – VINA DIP MOULDING COMPANY LIMITED

Tax code: 0107006928

Office address: Petrolimex Bldg No.9/84 Ngockhanh Str., Hanoi, Vietnam

Factory address: Lot 1-16 Duong Lieu IZ, HoaiducDist., Hanoi, Vietnam

Tel/ Fax: 0243 776 3021 – Email: cuongnm@vijaya-vina.com.vn

Hotline/ Zalo: 0974 876 389 – 0869 396 388 – 0869 317 388

Website: https://vijaya-vina.com.vn

Youtube Channel: https://www.youtube.com/@vijaya-vina

Fanpage: https://www.facebook.com/profile.php?id=100088634359963

Tiếng Việt

Tiếng Việt