News

15 Frequently Asked Questions About Metal PVC Coating

Are you interested in metal PVC coating services but still have many questions? Join Vijaya Sai Dip Moulding Vietnam Co., Ltd. as we answer the 15 most frequently asked questions to help you better understand this service!

Contents

- 1 Question 1: What is metal PVC coating?

- 2 Question 2: What products can be PVC-coated?

- 3 Question 3: What type of PVC is used?

- 4 Question 4: What are the benefits of metal PVC coating?

- 5 Question 5: Does PVC coating affect product size?

- 6 Question 6: Can PVC coating be customized in different colors?

- 7 Question 7: What is the PVC coating process?

- 8 Question 8: Which industries benefit from PVC coating?

- 9 Question 9: Can PVC coating be applied to all types of metal?

- 10 Question 10: How long does it take to complete PVC coating?

- 11 Question 11: Can the PVC coating withstand harsh environments?

- 12 Question 12: Can large-sized products be PVC-coated?

- 13 Question 13: Do you accept small quantity orders?

- 14 Question 14: How is the cost of PVC coating calculated?

- 15 Question 14: How is the cost of PVC coating calculated?

Question 1: What is metal PVC coating?

Metal PVC coating is a modern industrial process in which a metal product is coated with a layer of soft plastic (usually PVC) on its surface. The purpose of this process is to:

- Protect products from corrosion

- Increase electrical insulation

- Prevent scratches

- Improve aesthetic appeal

- Enhance durability in harsh environments

Question 2: What products can be PVC-coated?

Most metal products can be coated with PVC, including:

- Electronic components: Terminal lugs, busbars, electrical boxes

- Handles: Door handles, tool handles

- Brackets & Supports: Frames, hanging racks, pipe clamps

- Machine parts: Gears, washers, connecting rods

- Technical tools: Wrenches, pliers, and other mechanical tools

Question 3: What type of PVC is used?

We use high-quality soft PVC with outstanding properties:

- Heat resistance: Up to 105°C, suitable for various working conditions

- Electrical insulation: Withstands voltage up to 600V, ensuring safety

- Custom colors: Available for branding and aesthetic needs

Question 4: What are the benefits of metal PVC coating?

PVC coating offers multiple benefits, including:

- Product protection: Rust-resistant, anti-corrosion, and scratch-resistant

- Enhanced safety: Provides effective electrical insulation

- Aesthetic improvement: Smooth and uniform plastic coating

- Increased durability: Resistant to harsh environmental conditions

- Cost-effective: Reduces maintenance and replacement costs

Question 5: Does PVC coating affect product size?

The PVC layer is thin and uniform, typically ranging from 0.2mm to 1mm, depending on customer requirements. This does not significantly affect the size or shape of the product.

Question 6: Can PVC coating be customized in different colors?

Yes! We offer a wide range of color options and can customize colors according to specific requests. This is particularly useful for brand identity and aesthetic requirements.

Question 7: What is the PVC coating process?

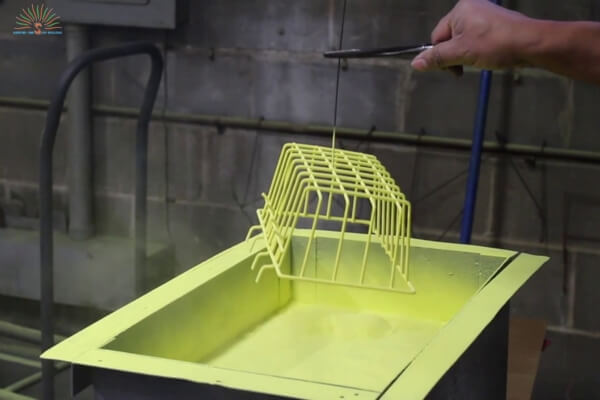

At Vijaya Sai Dip Moulding Vietnam, the PVC coating process includes:

- Surface preparation: Cleaning and degreasing to remove oil and dust

- Dipping process: Immersing the product in liquid PVC at high temperatures

- Cooling: Allowing the product to cool naturally or using a cooling system

- Quality inspection: Ensuring an even coating without peeling or defects

Question 8: Which industries benefit from PVC coating?

Metal PVC coating is widely used in many industries, including:

🏗 Construction: Pipe fittings, brackets

🏭 Manufacturing: Machine parts, mechanical components

🔌 Electronics: Busbars, terminal lugs

🏠 Consumer goods: Kitchenware, household items

Question 9: Can PVC coating be applied to all types of metal?

Most metals such as steel, aluminum, copper, and stainless steel can be PVC-coated. However, for optimal results, the metal surface must be properly treated before coating.

Question 10: How long does it take to complete PVC coating?

The turnaround time depends on the order size and specific requirements:

📌 Standard orders: 3-7 working days

📌 Large orders: Flexible timeline, confirmed upon order placement

Question 11: Can the PVC coating withstand harsh environments?

Yes! Our PVC coating is designed for durability:

☀ UV-resistant: Protects against sun exposure

🛡 Corrosion-resistant: Ideal for chemical or humid environments

🔥 Heat-resistant: Suitable for high-temperature applications

Question 12: Can large-sized products be PVC-coated?

Yes! We can coat large-sized products, depending on the capacity of our dipping tanks. Please provide detailed dimensions so we can assess and recommend suitable solutions.

Question 13: Do you accept small quantity orders?

Yes! We handle both small and large orders, catering to individuals and businesses. Even for small orders, we guarantee quality and fast turnaround.

Question 14: How is the cost of PVC coating calculated?

PVC coating costs are based on:

- Product size

- Order quantity

- Special technical requirements

We are committed to offering competitive and transparent pricing.

Question 14: How is the cost of PVC coating calculated?

PVC coating costs are based on:

- Product size

- Order quantity

- Special technical requirements

We are committed to offering competitive and transparent pricing.

Watch our PVC-coated product video!

Contact Information

Have more questions? Contact Vijaya Sai Dip Moulding Vietnam today for professional consultation and quick support!

VIJAYA SAI – VINA DIP MOULDING COMPANY LIMITED

Tax code: 0107006928

Office address: Petrolimex Bldg No.9/84 Ngockhanh Str., Hanoi, Vietnam

Factory address: Lot 1-16 Duong Lieu IZ, HoaiducDist., Hanoi, Vietnam

Tel/ Fax: 0243 776 3021 – Email: cuongnm@vijaya-vina.com.vn

Hotline/ Zalo: 0974 876 389 – 0869 396 388 – 0869 317 388

Website: https://vijaya-vina.com.vn

Youtube Channel: https://www.youtube.com/@vijaya-vina

Fanpage: https://www.facebook.com/profile.php?id=100088634359963

Tiếng Việt

Tiếng Việt